Friends, today in this article we will know about Deenbandhu Biogas Plant. I am going to give you information about all this in a very good way. So let’s start.

Types of Biogas Plant

There are two types of bio-gas plants-

(i) Floating gas holder commonly known as KVIC type. Pragati model is an improved version of this.

(ii) Fixed dome type plant commonly called Janata type.

Stationary Dome Bio-gas Plant

In this type of plant, the gas collector is also made of cement and brick like a digester and the dome remains stable. The entrance is made in such a way that the dung slurry can be displaced equal to the pressure of the gas so that the gas can collect in the stable gas collector. The gas pressure in the plant depends on the amount of gas. The following two designs are main in plants with stable domes-

(a) Janata Bio-gas Plant

(b) Deenbandhu Bio-gas Plant.

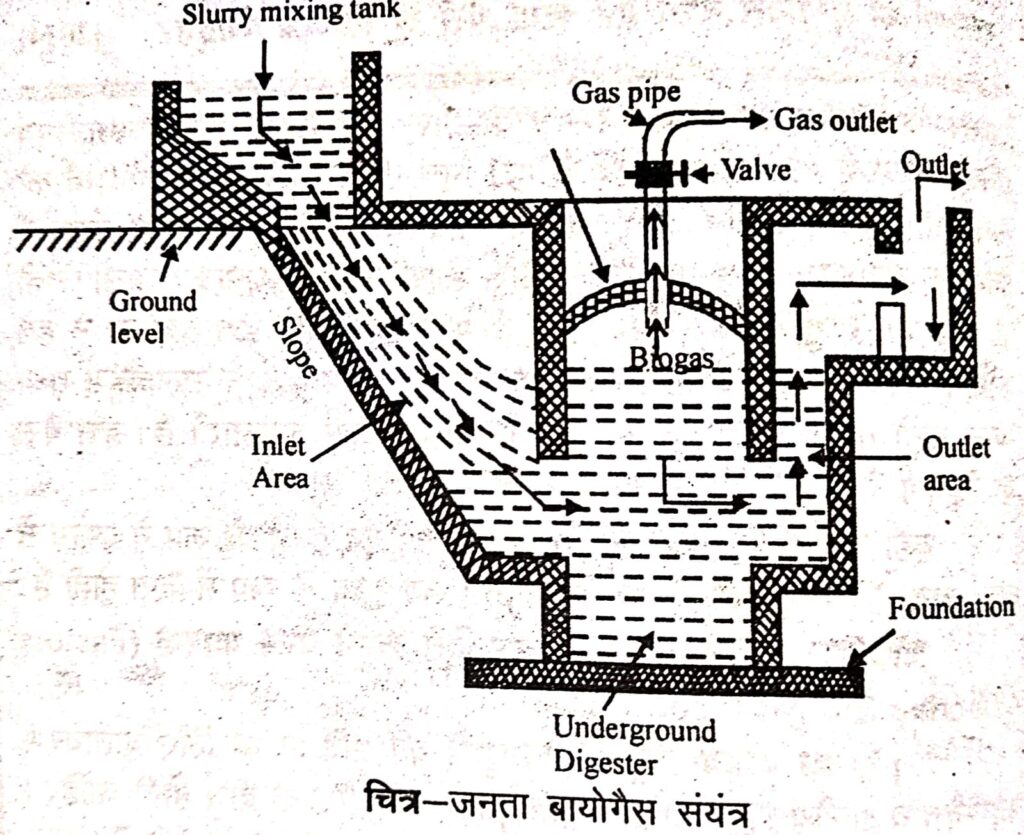

Janata Biogas Plant

These plants are made for a capacity of 2 cubic meters to 10 cubic meters. This plant is underground and is made of brick, cement, concrete etc. This plant is made of dome brick.

Its inlet is connected with a slope towards the digester so that the dung-water solution can easily enter the digester chamber. The exit door is made on the other side, its digester is made of simple masonry of cylindrical shape. Biogas is produced by rotting dung through bacterial action in the digester, which is stored in a dome, which is taken out with the help of a gas pipe and taken to the place of use. In this, the dung solution is displaced equal to the pressure of the gas and the digested slurry is collected in the exit area, which is taken out and used as fertilizer in the fields. This plant is comparatively less costly but the amount of biogas produced is also less.

Deenbandhu Bio-Gas Plant

This is a stationary dome plant, which has the lowest cost compared to other plants. Deenbandhu plant is a model developed by a non-governmental organization ‘Action for Food Production’ New Delhi.

modus operandi

- Digester- Its digestor is built at a certain height from the ground. It is made from simple mortar.

- Gas holder- It is a hemispherical part in which gas collects. It is made of brick, cement etc. at a certain height from the digestor. A gas pipe is installed above it to extract the gas.

- Entrance gate- It is wider at the top and narrower at the bottom and has a sloping shape towards the bottom from the sides. The mixture is poured into the digester from this.

- Exhaust gate- through this the rotten dung or manure is thrown out.

What did you learn today :-

Now you must have known about Deenbandhu Bio Gas Plant and you must have got the answer to all these questions well.

I hope you liked the information given by me, if you have any question/suggestion in your mind, then you can tell me by commenting below, I will definitely reply to your comment. If you liked this post, then you can also share it with your friends and relatives.