Friends, today in this article we will learn about open cycle marine power plant. I am going to give information about all this in a very good way. So let’s start.

The sea helps in producing two types of energy-

1. Thermal energy from the sun’s heat

2. Mechanical energy from tides and waves

The surface of the sea gets heated by the heat of the sun, which creates a difference in the temperature of the surface and the depth, which converts the heat into electricity. The temperature of the sea varies according to latitude and season. No fuel is required in marine energy sources. Thermal energy conversion plants are of two types-

(a) Open cycle system

(b) Closed cycle system

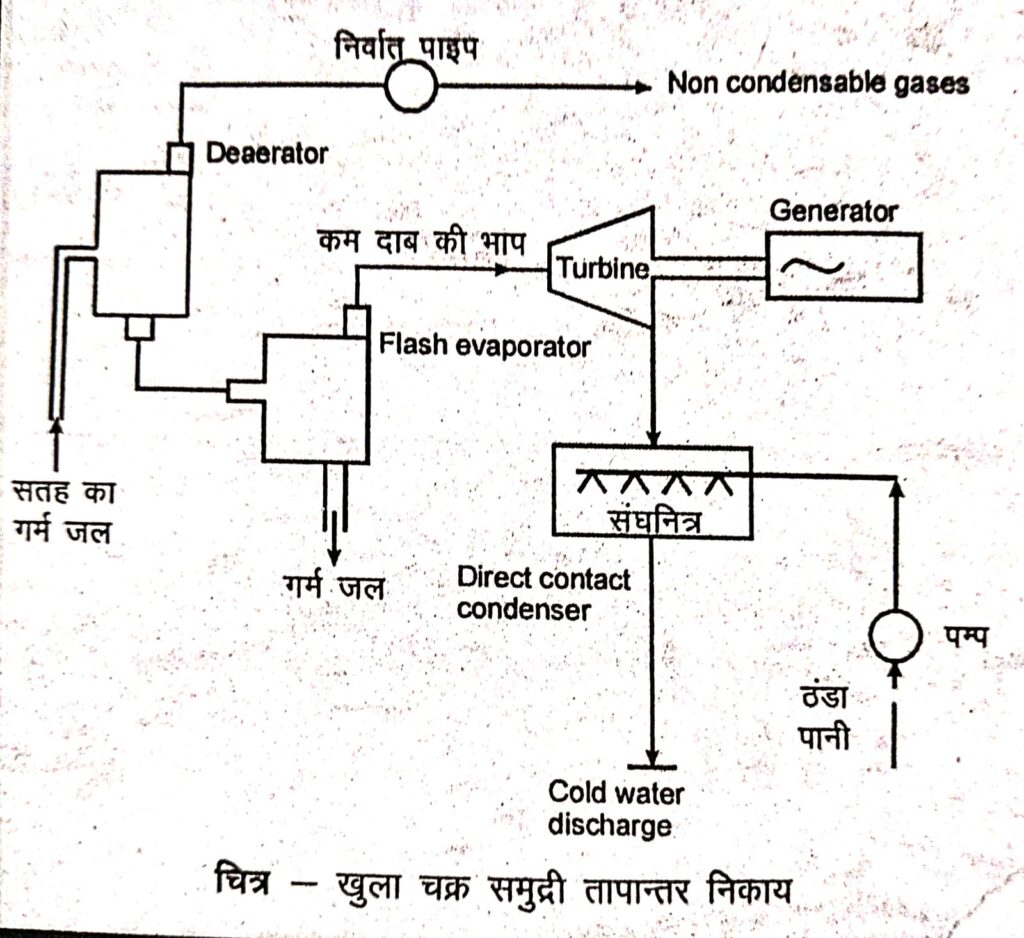

open cycle marine thermodynamic system

In this type of system, sea water is used as the working fluid. Low pressure steam is expanded in a turbine which is coupled to a generator. Then – the steam expelled from the turbine is passed into a condenser directly connected to it and the condensate is taken out and allowed to go into the sea.

In the direct contact condenser, cold water is pumped from the depths of the sea. It is called open cycle because the condensate does not have to be returned to the evaporator. As in the case of closed cycle system, it is either sent to the sea or if surface condensate is used, then the condensate is used for desalination of water.

The open cycle requires a larger quantity of water from the sea and a higher volume flow rate. The turbine is low pressure and large in physical size. Also, degasifiers are used to separate the dissolved gases from the sea water. There is no heat transfer problem in the evaporator and bio fouling control is also reduced.

The cost of producing adequate megawatt power in an open cycle system is higher than that in a closed cycle system.

Closed cycle system

The closed cycle marine temperature conversion system is shown in the figure below. The heat exchanger which acts as the evaporator or boiler and the condenser are the key components as they use low quality and low temperature heat and are constructed from special materials.

This fluid may be ammonia, propane or a freon. Such fluids have a working pressure higher than that of water at the evaporator and condenser temperatures. At the evaporator this pressure is about 10 kg/cm² or 10 bar and their specific volume is low.

Thus, with such pressure and specific volume, the turbine is smaller in size and its cost is also less than that of an open cycle turbine. The closed cycle does not have the problems of flash evaporation. But it requires large heat exchangers because for about 2% efficiency, 50 times more heat than the plant output has to be supplied and expelled. Also, the temperature difference between the evaporator and the condenser is kept as low as possible so that maximum temperature difference is maintained across the turbine. Hence, these units have a large surface area. In the Andeson cycle, propane was chosen as the working fluid. The temperature difference between the hot surface and the cold surface was 20°C. The hot surface was placed at a depth of about 600 m. The propane was evaporated at a pressure of about 10 kg/cm² or more and expelled from the condenser at about 5 kg/cm².

What did you learn today :-

Now you must have known about open cycle marine power plant and you must have got the answer to all these questions well.

I hope you liked the information given by me, if you have any question/suggestion in your mind, then you can tell me by commenting below, I will definitely reply to your comment. If you liked this post, then you can also share it with your friends and relatives.